All Rights Reserved: This image belongs to the photographer (Trevor Riedemann). If you wish to use it for any purpose, you'll need to obtain written permission from the photographer.

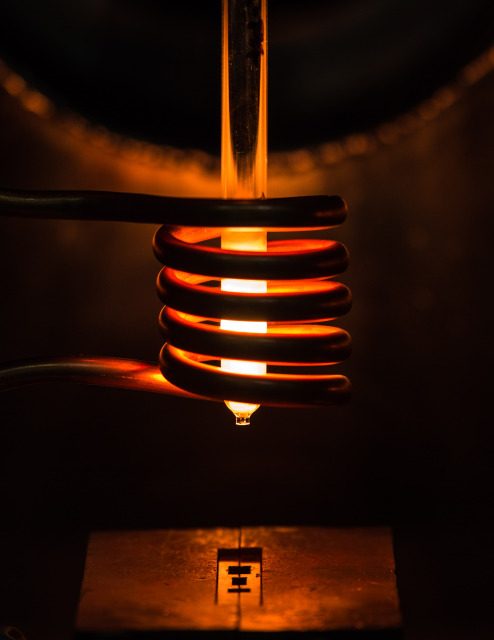

Induction Function II

Induction Function II. High frequency induction furnace coil with hot work piece. A molten metal is held in a quartz crucible in preparation for injection into the water cooled copper mold at the bottom. To inject the metal, the crucible will be lowered to 2mm above the mold and high pressure gas will force the metal out through the nozzle. That injection process is completed in under 1 second. The system is used for injection casting of metals which form metallic glass (amorphous metals).

Submitted by: Trevor Riedemann, AMES LABORATORY OF US DOE on June 23, 2016

Tags: Ames Laboratory, Metals Development Building, US DOE

0 likes 312 views